- Contributions by industrial experts with engineers in mind

- Focused on specialty-chemical material applications and selection

Knowledge Center

Industrial Cleaners Q&A

Industrial cleaners remove unwanted substances from the surfaces of parts and equipment used in manufacturing, maintenance, and repair operations. Examples of these substances include dirt and dust, abrasive and adhesive residues, and paints and greases. The types of surfaces that are treated with industrial cleaners range from machined metal parts and printed circuit boards (PCBs) to motors, shafts, screws, and fiber optic connectors – just to name a few.

For engineers who need help with product selection, this Q&A from Gluespec® provides answers to frequently asked questions (FAQs) about industrial cleaners.

Why is industrial cleaning necessary?

Industrial cleaners remove surface contaminants that can prevent adhesives, paints, or coatings from bonding to substrates. They can also remove these same substances after they’re applied. Importantly, there’s a relationship between cleaning and performance. In the case of optical substrates, for example, industrial cleaners remove residues from polishers that can interfere with light scattering and absorption. With electric motors, it’s important to remove contaminants that can increase motor temperature and reduce motor life.

What is the difference between an industrial cleaner and a commercial cleaner?

Commercial cleaners are used for removing dirt and grime inside public places such as schools, stores, restaurants, and hotels. They may also contain disinfectants. Although there are industrial cleaners that can perform similar tasks, this product category includes substances for more demanding or specialized applications. For example, some industrial cleaners can remove grease, strip paint, or remove stains from automotive fabrics. There are also specialized products for cleaning fiber optic connections.

What are some key considerations during industrial cleaner selection?

It’s important to specify both the substrate material and the substance or substances to remove. Most industrial cleaners are one-part products, but they vary in terms of material form, application method, and chemistry. Industrial cleaners also vary by color and odor, and some products meet specific regulatory requirements or safety-related standards. The way that a product cures, or achieves its final properties, can affect the speed of cleaning.

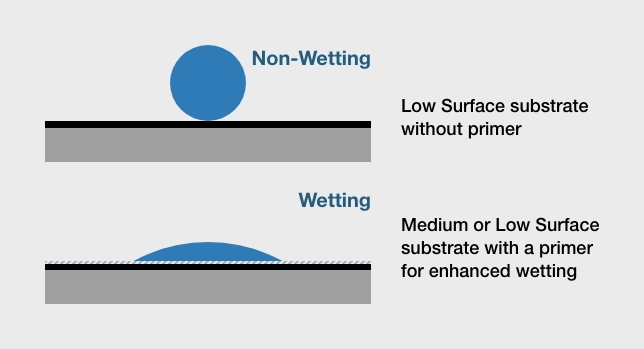

Why is the substrate material such an important product specification?

Most industrial cleaners are designed for specific types of substates. For example, some products are used for cleaning metal, glass, plastic, rubber, or composite materials. There are also industrial cleaners for concrete, wood, ceramic, or fabric. Because these categories of materials are broad, it may be necessary to narrow your search. For example, there are industrial cleaners for low surface energy plastics and for aluminum that is galvanized instead of untreated.

Can industrial cleaners remove uncured materials?

Some industrial cleaners like WEICON’s Power Cleaner S Spray can remove uncured materials from various substrates such as PMMA (acrylic glass), ceramics, glass, all metals, most plastics, PVC, polystyrene, and thermoplastics. Yet, other cleaners can remove uncured adhesive (such as epoxy adhesives) that were applied to misprinted PCBs. There are also products that can soften and remove resides from adhesive tapes. When searching for industrial cleaners on Gluespec, you’ll find subcategories called Cleaners – For Substrates and Cleaners – For Uncured Materials. Note that some products, such as Dow OS-30, belong to both subcategories.

What are the material forms for industrial cleaners?

Most industrial cleaners are supplied as liquids or aerosols. With aerosol spray cleaners, a liquid is dispersed as a mist for wide area or spot coverage. Aerosols dry quickly, but they tend to have higher levels of volatile organic compounds (VOCs), chemicals that usually contain industrial solvents. Liquid industrial cleaners take longer to dry but they contact surfaces for longer periods of time for deeper cleaning. Liquid cleaners come in bottles of various sizes as well as pails and drums.

What are some key considerations with solvent based cleaners?

Solvent cleaning is well-established and can remove surface contaminants in a variety of industrial applications. However, many of the conventional solvents that are used for cleaning, such as hydrochlorofluorocarbons, are subject to environmental health and safety (EHS) regulations. In some cases, there are regulations in place to reduce or phase-out these products. In addition, cleaning solvents that are toxic or flammable may require a ventilated area or respiratory protection.

Are water-based cleaners effective? How do they compare with solvent cleaners?

Water-based or aqueous cleaners are effective, but they have some important differences from solvent cleaners. For example, water-based cleaners have a narrower evaporation range. By contrast, some solvent cleaners evaporate instantly while others require extended periods of time to do so. Aqueous cleaners also have a narrower temperature range and a higher surface tension. Because they have a lower surface tension, solvent cleaners can reach tight spaces more effectively.

Is there a difference between dry time and cure time?

Dry time or drying time is the minimal time that’s required for an applied cleaner to reach the stage where it will no longer be affected by environmental conditions. Cure time refers to the amount of time that’s needed for an industrial cleaner to achieve its final properties. For example, Permabond ASC 10 is an industrial cleaner with a rapid dry time and a cure time of 1,440 minutes. Note that cure times are listed in conjunction with cure temperatures.

How do you apply industrial cleaners?

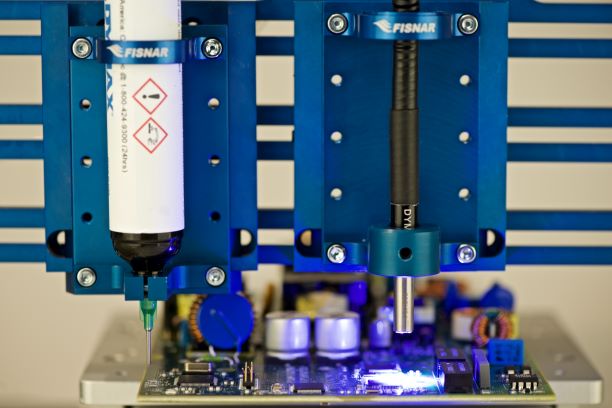

Industrial cleaners can be applied by hand or with automated or semi-automated equipment. For example, a worker can hold an aerosol cleaner in the hand and direct the spray toward part surfaces. Some industrial cleaners, such as products for cleaning fiber optic connectors, use a pen-style applicator instead. For large-scale industrial cleaning, such as with batches of metal parts that require degreasing, parts may travel on a conveyor for cleaning followed by drying with an air knife.

Are degreasers the same as industrial cleaners?

No. Degreasers are a specific type of industrial cleaner for removing greases: solid or semi-solid lubricants that contain various base oils, thickeners, and additives. Depending upon the specific formulation, degreasers can also be used to remove lubricating oils, cutting fluids, corrosion inhibitors, and even tar and asphalt. In general, however, degreasers are designed to clean surfaces with a minimal amount of wiping and scrubbing.

Why is chemistry important for industrial cleaner selection?

Industrial cleaners are available with many different chemistries but dividing them into acid vs. alkaline products is a useful distinction.

- Acid cleaning agents have a pH less than 7. They’re used to remove inorganic deposits such as weld and laser scales and oxides such as rust.

- Alkaline cleaning agents have a pH higher than 7. They’re used to remove organic deposits such as dirt, oils, and greases.

With acid cleaning agents, the active ingredients are usually strong mineral acids. Sometimes, surfactants and corrosion inhibitors are added. When alkaline materials interact with fatty acids, saponification occurs. In layman’s terms, this chemical reaction produces soap.

What is a debonder?

A debonder is an industrial cleaner that breaks or weakens the bonds between two materials or surfaces. Often, these products are used to remove adhesives without damaging the substrate or substrates. Typically, debonders are used during rework and disassembly; however, they’re sometimes used during maintenance and repair activities. Some debonders are formulated for specific adhesive chemistries such as cyanoacrylate, which is commonly known as super glue.

What is a remover?

A remover, or stripper, is an industrial cleaner that’s designed to remove paint, finishes or coatings while also cleaning the underlying surface. There are several different types of products. Caustics work by breaking down the chemical bonds. Solvent strippers penetrate the layers of the paint, finish, or coating and cause swelling that breaks the bond with the substrate. Activators may be used to increase the penetration rate of the product.

Are industrial cleaners used in electronics?

Yes. There are products for removing conformal coatings, potting compounds, encapsulants and dielectric gels. When cleaning PCBs, it’s important to consider the parts to clean, the substrate material, and the type of solder flux or paste. Today, many PCB assemblies (PCBAs) contain components made of different materials, such as metal, copper, ceramic, and glass. The way a PCBA was processed, such as with wave flow soldering, may also be a factor.