- Contributions by industrial experts with engineers in mind

- Focused on specialty-chemical material applications and selection

Knowledge Center

Lubricants In-Depth: Pastes

Paste Lubricants

Paste lubricants are a particular kind of lubricant that rely more on the solid lubricants they contain than liquid-based lubricants like oil or greases.

Pastes are a particular kind of lubricant that rely more on the solid lubricants they contain than liquid-based lubricants like oil or greases. Pastes provide friction-reduction by creating a barrier between two surfaces, using solid-lubricant compounds to coat surfaces, allowing a more uniform, lower-friction interaction that reduces wear, heat and other negative impacts of friction. Generally pastes are used in low-speed, high-load applications.

What are paste lubricants?

Pastes are made up of 50-70 percent solid lubricants, with molybdenum disulfide (MoS2), polytetrafluoroethylene (PTFE) and graphite the most common. The other components in pastes are mostly mineral or synthetic oil. They can be applied by brushing or dipping, and some can be in aerosol form. Depending on their formulation, they can be used in environments over 1000C, and their lubricating properties generally aren't affected by gravity, speed or pressure.

Pastes are often broken down into different categories including black pastes, white pastes and metal pastes.

- Black pastes - usually contain MoS2 and/or graphite, used for assembly and general purpose applications.

- White pastes - usually contain PTFE, phosphates and/or hydroxides, used for assembly and preventing fretting and welding caused by vibration.

- Metal pastes - usually contain other solid lubricants and metal powders, often used for threaded connections.

Other types of pastes, like metal-free pastes can be used where environmental concerns are paramount. Pastes that meet FDA 21 for incidental food contact listed as H1 are available as well.

How do paste lubricants work?

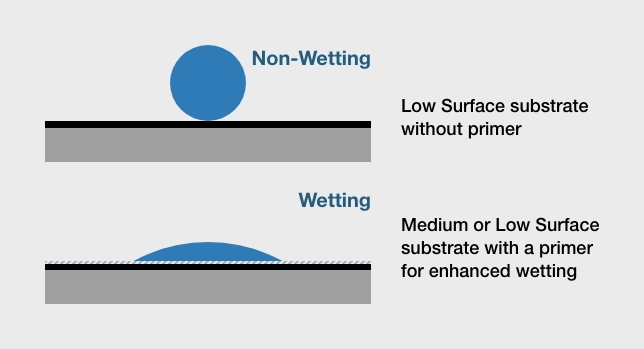

Whereas in other lubricants the liquid components provide primary or additional lubrication, in pastes these compounds are called carriers and are mostly designed to help wet-out, or coat, surfaces more uniformly. The carrier in pastes can be designed to evaporate without residue under high temperatures, leaving a thin, lubricating film behind that adheres to the surface. This thin film of solid lubricant fills in microscopic irregularities on surfaces and smoothes over asperities that would ordinarily interfere under load. Because the solids are providing lubrication with pastes, they can be used under extremely harsh conditions, with much higher loads and temperatures than oils or greases alone.

"Pastes can prevent other problems with threaded connections such as galvanic and regular corrosion, welding and fretting."

How are paste lubricants used?

Pastes have more specific uses than other general-purpose lubricants. Sometimes referred to as anti-seize pastes, they can be used to reduce or eliminate seizing of bolts. Normally threads do not contact each other uniformly during assembly, which causes high stress to be concentrated in a small area. This concentrated stress can lead to galling and potentially seizing. The coating of bolts in pastes has the effect of creating a more consistent coefficient of friction which allows smoother assembly and disassembly. Pastes can also prevent other problems with threaded connections such as galvanic and regular corrosion, welding and fretting.

In addition to their use in threaded connections, pastes find frequent use in the running-in of new machinery, gears, engines and other equipment. They are also used in press-fitting of metal connections, spindles, parts of brake systems, and axle assembly. Their use during these operations can increase the lifetime of parts and reduce possible damage.